Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- 954 All Categories

- 3 Picture Posting and Resizing

- 60 New Member Introductions

- 100 Off-Topic Forum

- 2 Photography

- 2 Resources

- 18 New Product Information

- 164 The SierraWest Forum

- 11 Brett's Blog

- 120 General News & Ramblings

- 3 Re-Release Information

- 1 Q & A about SierraWest

- 9 What Would You Like to See?

- 405 Builds

- 145 HO Scale Builds

- 185 O Scale Builds

- 58 Finished SW Build Pics

- 11 Miscellaneous Builds

- 185 Techniques

- 19 Working with Wood

- 23 Painting Castings

- 4 Masonry

- 16 Scenery

- 37 Tools and Supplies

- 22 Layout Planning & Building

- 38 Miscellaneous

- 19 Prototype Information

- 18 Reference and Research

The Dr. Grunge Advanced Wood Clinic

Following much procrastination, I call it detail planning, I am kicking off the Dr. Grunge Advanced Wood Clinic. It was suggested that I contribute to this clinic, as I would not have been so presumptuous to have started this on my own. There are so many wonderful modelers here on the forum that I am humbled to be able to "knock elbows" with you guys and talk some shop.

First and foremost, and please remember, the techniques and methods are not "how to do it", but rather just "how I do it". We are all unique in how we go about detailing stripwood. There is no right or wrong, success or failure, however, to achieve a desired result there are some guidelines.

I cannot over emphasize the contribution Brett has made to this hobby and to the "science" of detailing stripwood. If I don't have anything else, I have enthusiasm! I studied Brett's manuals and his methods for detailing stripwood and came to the realization early on that if I could, in my mind, master the art of detailing the wood I would be well on my way to achieving the results I envisioned. Brett instilled in me the concept that the coloring, detailing, and general care of the stripwood is the single, most important, factor to a realistic and quality model. I took this to heart and spend more time and get more enjoyment out of working with wood than anything else. It lays the foundation to the character and story your model will betray.

I stated "Advanced Wood Clinic" which I believe warrants some clarification. Brett provides comprehensive instructions for detailing stripwood in two main formats:

1. The manuals included in each and every SWSM kit. My advice is study these manuals carefully. They are tried and true methods and if followed will result in a superior, beautifully detailed structure.

2. The Craftsman Kit University, accessible from the SWSM Home Page. Go to Online Clinics and then select

"Adding Texture and Details to Stripwood". This is an excellent tutorial that compliments the manual instructions. This tutorial is supported by the video link "Adding Details to Stripwood".

With this plethora of detailed information Brett provides on detailing and finishing stripwood, it begs the question; why have the clinic presented here?

Brett lays the foundation for quality, highly detailed, stripwood in the above tutorials. However, the modeler will develop his or her own variations, techniques, and styles. This clinic will explore what I like to do with my wood and how I achieve the results that you've may have seen here on the forum. We are attempting to do in an afternoon what nature and the elements take years to do. So, if we are able to achieve this type of weathering and detail in a short time...that's some powerful stuff and creates a structure full of character and realism. So off we go...

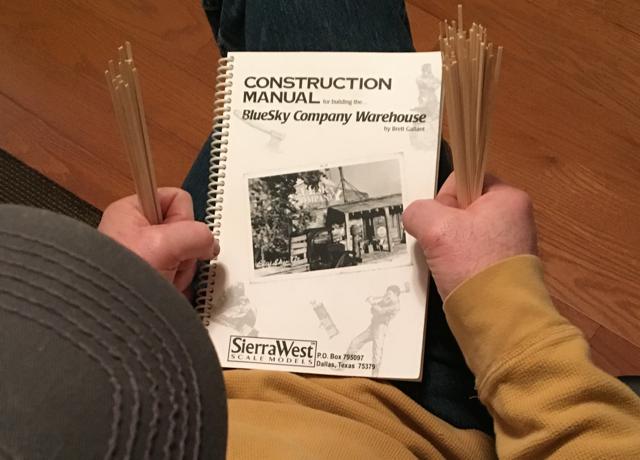

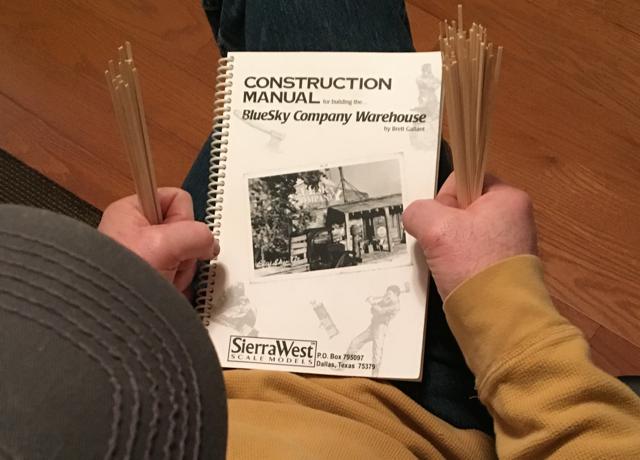

This is our first glimpse of our beloved SierraWest Scale Models stripwood. This gathering happens to be from the Loco and Service Shops kit. Brett carefully packages and sorts the stripwood and seals them in individual labeled bags. In my experience his wood is always of high quality, details beautifully, and is sorted and packaged for ease of use and assembly.

So...grab a fist full and lets grain and stain some wood!

Is that a BlueSky Company Warehouse manual?...more on that later.

First and foremost, and please remember, the techniques and methods are not "how to do it", but rather just "how I do it". We are all unique in how we go about detailing stripwood. There is no right or wrong, success or failure, however, to achieve a desired result there are some guidelines.

I cannot over emphasize the contribution Brett has made to this hobby and to the "science" of detailing stripwood. If I don't have anything else, I have enthusiasm! I studied Brett's manuals and his methods for detailing stripwood and came to the realization early on that if I could, in my mind, master the art of detailing the wood I would be well on my way to achieving the results I envisioned. Brett instilled in me the concept that the coloring, detailing, and general care of the stripwood is the single, most important, factor to a realistic and quality model. I took this to heart and spend more time and get more enjoyment out of working with wood than anything else. It lays the foundation to the character and story your model will betray.

I stated "Advanced Wood Clinic" which I believe warrants some clarification. Brett provides comprehensive instructions for detailing stripwood in two main formats:

1. The manuals included in each and every SWSM kit. My advice is study these manuals carefully. They are tried and true methods and if followed will result in a superior, beautifully detailed structure.

2. The Craftsman Kit University, accessible from the SWSM Home Page. Go to Online Clinics and then select

"Adding Texture and Details to Stripwood". This is an excellent tutorial that compliments the manual instructions. This tutorial is supported by the video link "Adding Details to Stripwood".

With this plethora of detailed information Brett provides on detailing and finishing stripwood, it begs the question; why have the clinic presented here?

Brett lays the foundation for quality, highly detailed, stripwood in the above tutorials. However, the modeler will develop his or her own variations, techniques, and styles. This clinic will explore what I like to do with my wood and how I achieve the results that you've may have seen here on the forum. We are attempting to do in an afternoon what nature and the elements take years to do. So, if we are able to achieve this type of weathering and detail in a short time...that's some powerful stuff and creates a structure full of character and realism. So off we go...

This is our first glimpse of our beloved SierraWest Scale Models stripwood. This gathering happens to be from the Loco and Service Shops kit. Brett carefully packages and sorts the stripwood and seals them in individual labeled bags. In my experience his wood is always of high quality, details beautifully, and is sorted and packaged for ease of use and assembly.

So...grab a fist full and lets grain and stain some wood!

Is that a BlueSky Company Warehouse manual?...more on that later.

Comments

As you know, I am always asking you how did you achieve that look? Your weathered wood is exceptional and the results are, in my opinion, what we are all trying to achieve. Is the magician going to let us see how he does it? I hope so.

Mitch

Geezerbill

David

Michael

Happy New Year. Phil

Geezerbill

So, am I going to move right to adding texture to our stripwood?...ahh..no! If you're looking for a thread on stripwood detailing that's a few paragraphs long, this isn't the one. My plan is to take you through my entire process including my thoughts, philosophy, methods and peculiarities as it pertains to detailing my wood. Very little is my own and anything that appears to be my own was likely spawned from others work. I do however, hope I have developed my own style and many of you have expressed satisfaction with the results I have obtained. All techniques are within the scope of SierraWest Scale Models materials. No mysterious solutions with "eye of newt", or any concoction that will take a dedicated internet search to obtain. Any errors are my own but I take no responsibility for shoddy modeling! A phenomenon I have yet to see on this forum. I don't rush my modeling, as most of you know, so I'm not going to rush through this.

So, have I lost a good number of you?...good...then we're down to the serious modelers.

I'll get into what I do before actually working with the wood tomorrow...

Your structures (and specifically the wood) have qualities that are different and unique, making them unmistakable as a "Ken Karns" project. I'm SO looking forward to this.

If you're taking attendance, mark me as "present"!

Geezerbill

Carl

Geezerbill

The first thing I do, following my studying of the manual and kit contents, is make a decision as to how much texture I want to put into my wood. This is a personal decision based on how I want my structure to look and the character it will posess. This is actually a big deal, as it is easy to add more texture but much harder, if not impossible, to remove it if you go too far. Stands to reason that the more texture that is put into the wood the more weathered it will appear. At least that's what it will look like was being done, which is why the level of texture and weathering should fit the overall structure age and level of deterioration.

So I have decided how much texture I want and I have my stripwood sitting in front of me. The next thing I reach for is the tool(s) used to create the initial texture. This initial texture is followed by the coloring of the wood which is then followed by the really fun stuff...the individual board details...more on that later.

So for now the word "texture" will be replaced with "wood graining". Bare stripwood is just that bare. We want to create the illusion that the wood at least somewhat old and weathered. Keep in mind that not everything prototypical looks good once scaled to 1:87 (my medium). I perform wood graining as the initial step for ALL my stripwood regardless of how it will be used, unless of course it's being used where it won't show for some reason. The only tool I use for my initial wood grain work is a small steel wire scratch brush. There are many steel brushes out there and every modeler has their favorite which is perfectly fine. Mine is shown below...my hired hand model is showcasing the type I use.

This wire brush has the following attributes that makes it my choice for 1:87 scale grain work:

1. Bristles are not overly stiff. Now this aint science but here's my theory on why that may or may not be important. Stripwood already has wood grain. The wire brush shouldn't create the grain rather enhance and define it...make it pronounced in a hurry like nature does over time. If the bristles are too stiff they tend to make the grain where as the more pliable bristles follow the original grain removing material as it goes. The extreme example is a razor saw that totally ignores the original grain and makes uniform grooves in the wood. We'll discuss this more later.

2. This brush is very easy to control due to it's small size. I am able to "feel" the brush working the wood, which I like.

3. The brush is readily available from numerous sources and is fairly cheap to purchase. They don't however, last all that long. This is not a life long tool!

You guys modeling larger scales, and bigger wood, may want a larger brush. I work with only 2-3 pieces of wood at a time. Any more than that and I feel I don't have the control I need. So I place the pieces on my bench. I use a piece of solid oak wood to lay my stripwood on to brush. I then brush the wood back and forth until I get the grain pop that I want. I have done this enough I just have a good feel for when I've got the level of detail I want. If you're not sure on how much texture you want, perform some work on some test pieces first.

The following is some stripwood I grained as described above. This wood is from the classic BlueSky kit...more on that later.

This close up shows the wonderful natural grain that has been worked into the wood. The next step involves fine tuning this wood in preparation for "Staining". I will use the word "staining" to include any method used to color the wood. More next time...

Geezerbill

Thanks Bill...hopefully we'll be getting into some useful stuff soon..

I collect a wad of fine steel wool about the size of a golf ball and fold it in half between my thumb and fore finger...and with a pinching action I pull or draw each piece of stripwood individually through the steel wool. This action with my finger and steel wool in one hand and the stripwood in the other I can control where the pressure and action of the steel wool is being effective. You want more pressure along the edges, which is where most of the fuzzies are, and less on the face of the wood. This results in two quite effective actions:

1. Removes 90% of the fuzzies.

2. Serves to knock down the sharper ridges of the graining process giving a nice warm weathered appearance to the wood.

Yes, this process is time consuming and a bit messy as the steel wool will shed small steel fibers all over the place so do this over a trash can or piece of newsprint or something similar. You also must check the wood carefully as a few steel fibers may get stuck in the wood and must be removed. Take this process into account when you grain your wood as the steel wool will reduce the impact of the grain just a bit. Also, do not overdo this, just enough to clean up the frizzy wood. I believe you must be vigilant here as too many fuzzies will ruin an otherwise well detailed wall.

NOTE: The amount of fuzzies produced is based on two main variables; One is how aggressive you are with the wire brush work (pressure, time, and bristle firmness) and secondly the quality and hardness of the stripwood. Soft poor quality wood is miserable to work with. The wood Brett provides us is top quality and works up extremely well.

Depicted below is an example that illustrates the problem and solution....

Problem: Note the small splinters and pieces adhering to the wood following the graining with the wire brush, this is what we call the "fuzzies". Not good...

The same wood after being treated with the steel wool process outlined above. Good...

Note how the grain is virtually unaffected by the procedure. Also good...

As I continue to work with my boards any stray pieces of frizz are removed using a good pair of fine forceps. As the boards are detailed later on these scattered pieces will crop up but are much easier to deal with once the initial treatment is done.

Next up will be some notes on staining and then the individual details...