Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- 954 All Categories

- 3 Picture Posting and Resizing

- 60 New Member Introductions

- 100 Off-Topic Forum

- 2 Photography

- 2 Resources

- 18 New Product Information

- 164 The SierraWest Forum

- 11 Brett's Blog

- 120 General News & Ramblings

- 3 Re-Release Information

- 1 Q & A about SierraWest

- 9 What Would You Like to See?

- 405 Builds

- 145 HO Scale Builds

- 185 O Scale Builds

- 58 Finished SW Build Pics

- 11 Miscellaneous Builds

- 185 Techniques

- 19 Working with Wood

- 23 Painting Castings

- 4 Masonry

- 16 Scenery

- 37 Tools and Supplies

- 22 Layout Planning & Building

- 38 Miscellaneous

- 19 Prototype Information

- 18 Reference and Research

Lighting Clinic

Hey Gang,

Brett asked me to post a thread on Lighting. Disclaimer, there are many different options when lighting your dioramas. The process I'm going to walk you through is the one I use and is probably the most expense and the most time intensive lighting solution we can use when lighting up our dioramas but in return, it allows for the highest level of realism.

Let's get started:

The first step is youre going to need the following tools which can be purchased thru ngineering.com or Microlumina.com. I know Brett doesnt like links to other websites on his forum but its important you know where you can obtain these things as there are very few websites that specialize in lighting products for this small of an application.

Safety Glasses - I purchased these at Home Depot. This is very important you wear these when applying solding as I've had HOT solder "jump" off the Solding Iron numerous times and onto my face. When that occurs, its just a brief sting and doesnt leave a mark..but you're not going to want this stuff in your eyes.

Soldering Irons - You will need both a Regular Soldering Iron which can be purchased at Home Depot and a Low Temp Soldering Iron found at one of the websites listed above.

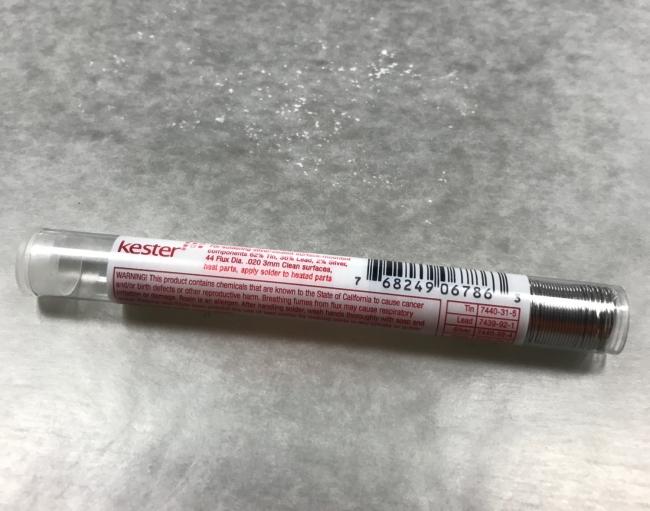

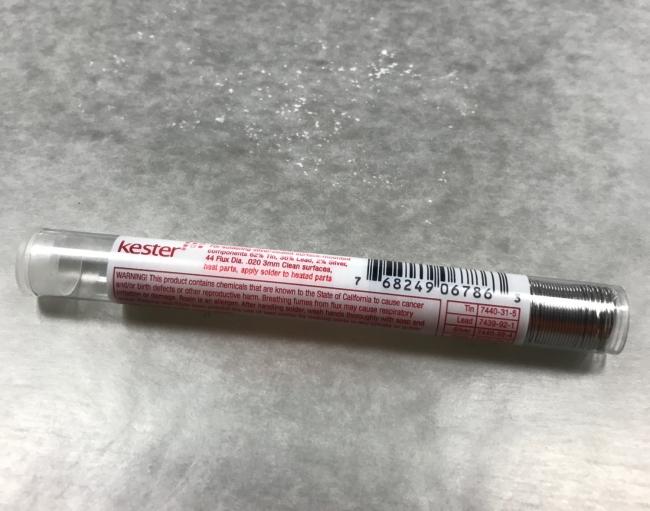

Low Temp Solder - You can NOT just use any old solder as the Low Temp Soldering Iron wont melt anything but Low Temp Solder.

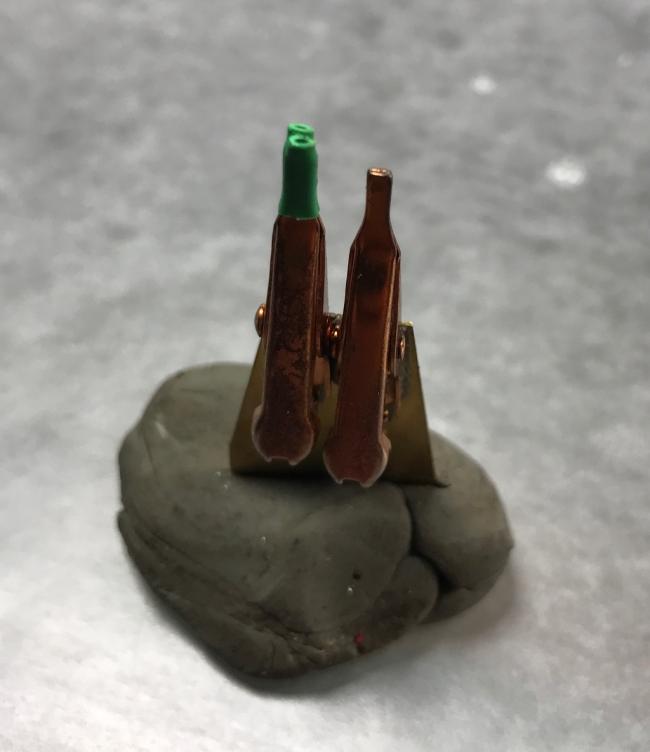

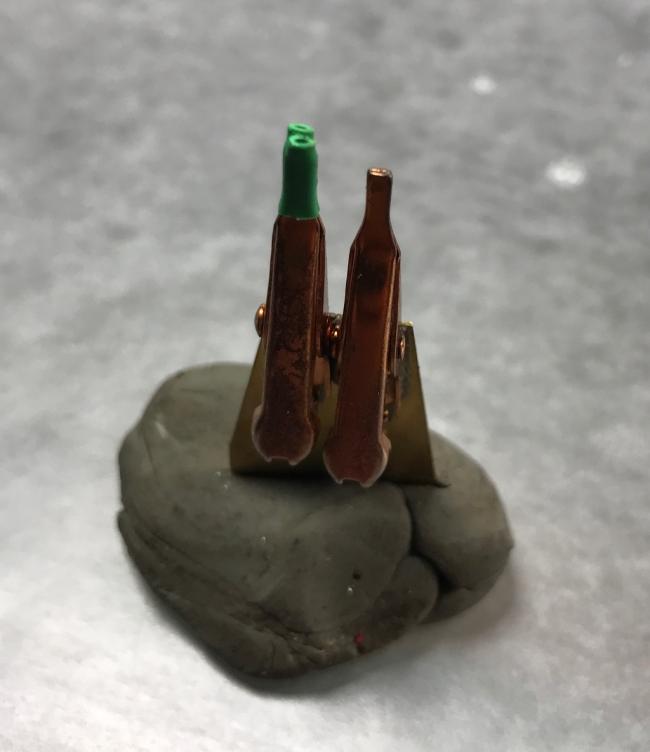

LED Holding Tool - You will need this when wiring the LEDs. For whatever reason, it doesn't come with a stand probably because its suppose to be put into a vice. Instead I push it into a blob of modeling clay.

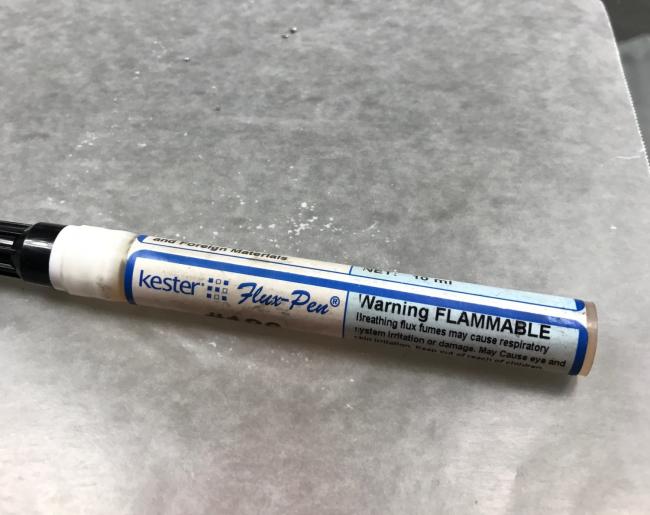

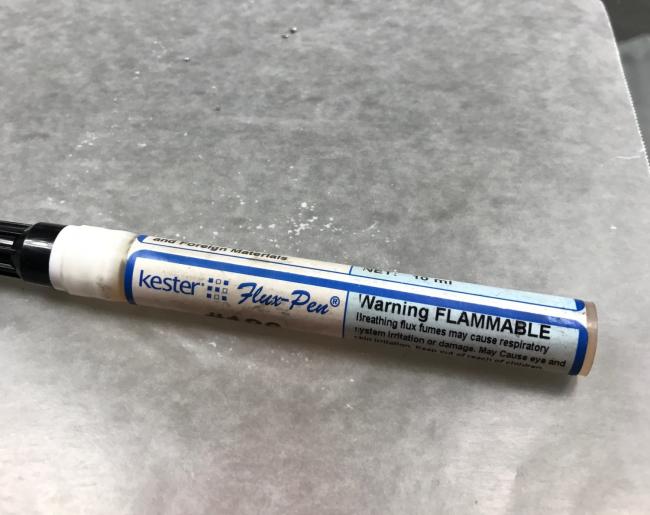

Flux Pen - This helps with the flow of solder which in turn creates a better bond to our LEDs.

Solder Tip Cleaner - Used to clean the old solder off your Soldering Irons

LED Tester - This is very important because it allows us to test our LEDs to insure we wired them correctly.

Pair of clippers to cut the various wires we will be working with during this Clinic - Bought mine at HobbyLobby

Wire Strippers - Think I got them at Home Depot

Meter - We will use this to make sure our Resistors are installed correctly

Electrical Tape

Sponge

This is a list of all the tools you will need for installing LEDs. Most of these items are a one time cost with the excepttion of the Solder. The next post will be a list of the supplies you need and is based on the goal of your project.

Brett asked me to post a thread on Lighting. Disclaimer, there are many different options when lighting your dioramas. The process I'm going to walk you through is the one I use and is probably the most expense and the most time intensive lighting solution we can use when lighting up our dioramas but in return, it allows for the highest level of realism.

Let's get started:

The first step is youre going to need the following tools which can be purchased thru ngineering.com or Microlumina.com. I know Brett doesnt like links to other websites on his forum but its important you know where you can obtain these things as there are very few websites that specialize in lighting products for this small of an application.

Safety Glasses - I purchased these at Home Depot. This is very important you wear these when applying solding as I've had HOT solder "jump" off the Solding Iron numerous times and onto my face. When that occurs, its just a brief sting and doesnt leave a mark..but you're not going to want this stuff in your eyes.

Soldering Irons - You will need both a Regular Soldering Iron which can be purchased at Home Depot and a Low Temp Soldering Iron found at one of the websites listed above.

Low Temp Solder - You can NOT just use any old solder as the Low Temp Soldering Iron wont melt anything but Low Temp Solder.

LED Holding Tool - You will need this when wiring the LEDs. For whatever reason, it doesn't come with a stand probably because its suppose to be put into a vice. Instead I push it into a blob of modeling clay.

Flux Pen - This helps with the flow of solder which in turn creates a better bond to our LEDs.

Solder Tip Cleaner - Used to clean the old solder off your Soldering Irons

LED Tester - This is very important because it allows us to test our LEDs to insure we wired them correctly.

Pair of clippers to cut the various wires we will be working with during this Clinic - Bought mine at HobbyLobby

Wire Strippers - Think I got them at Home Depot

Meter - We will use this to make sure our Resistors are installed correctly

Electrical Tape

Sponge

This is a list of all the tools you will need for installing LEDs. Most of these items are a one time cost with the excepttion of the Solder. The next post will be a list of the supplies you need and is based on the goal of your project.

Comments

LEDs - For O scale, I can get away with using 2x3 sized Super Incandescent Colored LEDs. They sell the LEDs in other colors but Ive found the Incandescent color gives off that Warm Lighting Effect we see in most of our interior lighting. For HO Modelers, youre going to want to use the Micro Super Incandescent LEDs..which are smaller but are a much better scale for HO.

Before I move on, there are two popular options when lighting dioramas. LEDs which I will discuss in this clinic and Grain of Rice which can be seen in Brian Nolan's Famous O Scale Dioramas. There are 2 reasons I chose LEDs for my lighting solution. 1st Reason - they are much smaller than the Grain of Rice Bulbs. It allows me to put the bulbs into smaller / tighter spaces for additional realism. 2nd Reason - They last much longer - actually, they will probably out live us all.

Pack of Resistors - For this O scale diorama, I chose 1K Resistors. For my HO Builds, I typically use 3K Resistors to make the light look more to scale. You dont want your LEDs too bright or it wont look right.

Power Board and Power Supply. The power board acts like the control center for the project. Its going to be where we install all of our resistors, link up all of our LEDs and attach the power supply that gets plugged into the wall.

Magnet Wire - This is really thin wire that allows us install our LEDs in small and tight places. The spool comes with both Red and Green Wire on it. If I were installing a Goose-neck Lamp, this wire is thin enough to fish thru a small tube.

Hookup Wire - This is thicker wire that allows us to connect our LEDs to the Power Distribution Board. You will use the Wire Strippers I listed in the Tools Section on these wires. They only come one color to a spool. The colors really dont matter too much. I chose Red (for Hot) and Black (for Cold).

Lamp Shades - They come in different sizes based on the Scale you're working with.

These are all the items I'll need for this project. Next up is how to wire an LED.

Step 1 - After our Regular Soldering Iron is Hot, you are going to melt some of your Low Temp Solder onto the end creating a blob. The reason we are using our Regular Soldering Iron here is because our Low Temp Soldering Iron doesnt get hot enough to melt the outer protective casing on our Magnet Wire.

Step 2 - One at a time, take a piece of magnet wire and either pierce/poke/or just hold it up next to the Blob of Solder on the end of your Soldering Iron. We are looking to "Tin" just the very end of the wire. You are going to repeat this process until both ends of both pieces of Magnet Wire have been Tinned. We dont want a blob of Solder on the end of the Magnet Wire. If this happens to you, just cut or "snap it" off and re-tin the end.

Step 3 - Pull out LED from the package and set on the Table. One end of the LED will have a small Black Line. This represents the Cathode or Cold Side of the LED. This tells us the side we will solder the Green wire to the LED.

Step 4 - Pull out your LED Holding Tool and insert your LED upside down into the tool. Looking at the picture below, the black line is on the right side of this LED..just underneath it since I turned it upside down. The LED is turned upside down to expose the Solder Pads - The connection point between the LED and the Tinned Magnet Wire.

Step 5 - Take an end of the Tinned Green Magnet Wire and insert it into the holding tool. You will want to bend the end of the wire over the end of the LED as shown. At this point, you will take the Flux Pen and dab it against the area where the wire meets the Solder Pad. By doing so, it will allow the Solder to flow more easily around the wire creating a better Solder Connection.

Step 6 - Melt a small dab of the Low Temp Solder onto the end of the LOW TEMP Soldering Iron.

Step 7 - Lightly touch the dab of Solder onto the area where the wire touches the Solder Pad on the LED. This is the only part of the process that is not an exact science. Sometimes it takes the first time and other times I have to go back with a second or third application of the Solder. The key here is dont hold the tip of the Low Temp Soldering Iron too long against the LED or it could melt it. More than 3-4 seconds is probably the limit. If the tinned end of the green wire hangs down too far, just use your clippers to trim off any excess. Just make sure you dont cut into your LED or the Solder Joint you created.

Step 8 - The first connection should now be complete. You can squeeze on the clamp of the LED Holder and Remove the LED. The connection should be strong. If for whatever reason the wire comes off as your removing the LED, repeat step 7. You will now flip the LED so that you can hook up the Red Magnet Wire to the other end. When I say flip, the Green Wire which is now connected should be on the left and the Solder Pad that gets the Red Wire Soldered to it should be on the right.

Step 9 - After both wires have been Soldered to the LED, its time to test it. Take the ends of the Tinned Red and Green Wire and Plug them into the Tester. The Green Wire goes into the Black Side and the Red Wire goes into the Red Side. It doesnt matter which color you plug in first, you will not blow out your LED...this part is Dummy Proof. Depending on how well you Tinned the end of the Magnet Wire, you may need to adjust / jiggle the connections a little to get your light to work.

If you'd like a better or more detailed description on how to wire an LED or trouble shoot any issues you might be having, I would advise you to visit the ngineering website. In addition, both Tim - The owner of Ngineering and Bill - aka Slim of Microlumina are extremely helpful and will respond to both phone calls and emails.

Next up is installing the LEDs in a Lampshade....

I next paint the entire shade white...usually with a few coats. After this I fish the 2 Magnet Wires thru the hole I created and glue the LED into place. After the glue has dried, I will paint the top of the Lampshade. For this project, I chose a Tarnished Silver. If you're looking for the more formal and traditional look, I would probably choose a Green.

I next hang the LED as if it was being hung in my building. We need gravity to help us with this next step.

To get the glass bulb look to the LED, I use Gallery Glass - Color is Crystal Clear.

It has the consistency of Elmers Glue but dries hard and clear. I squeeze a little on my work bench and apply it to the face of the LED with a tooth pick.

It will take 3-4 coats to build up that nice dome look. If you dont hang the light as I show in the picture, the Gallery Glass will run to where gravity wants to take it wrecking the look we are trying to achieve. After everything is dry, I'll use some rust colored chalk on both sides of the lamp. Here is what they look like installed...

Next up is connecting the ends of the Magnet Wire to Hookup Wire.

Bill

-Steve

When I last left off, I had shown how to connect Magnet Wire to an LED. The next step is to connect the Magnet Wire to a Hook Up Wire so we can link them up to the Power Distribution Board. In addition, the Hookup Wire is a much thicker which will allow us to feed the wires thru the base of our Diorama. Again, the reason we dont use the Hookup Wire directly with our LEDs is because the wire is too thick.

For my Project, I'm putting 5 Lamps in my Repair Shed. I will cut 5 - 3 foot pieces of Red Hookup Wire and 1 - 3 foot piece of Black Wire. I then will use the Wire Stripper to expose both ends of each Hookup Wire.

The next step is to take the end of one of the Red Magnet Wires and wrapped it around the end of one of the Red Hookup Wires that we just stripped the ends on. I then take the Flux Pen and rub some Flux across this connection.

You will now let your Regular Temp Soldering Iron heat up for 5 minutes or so and then put a blob of Low Temp Solder on the tip and rub it against the connection in the picture above. I over did the blob of solder so you could see it better. It honestly doesnt matter how much Solder you use...just enough to make a solid connection.

After the Solder Joint has cooled for a minute, cut a little piece of Electrical Tape and wrap the joint. I repeated this process of all 5 Red Magnet Wires.

During this process, the end of your Solder Tip might become caked with old solder. To remove it, place it into the Tip Cleaner I listed in the Tools Section and the rub the end of the Solder Tip across a Wet Sponge.

For the 5 green wires, these are your grounds. They can all be combined into one solder connection. Follow the steps I described above but wrap all 5 Green Maganet Wires around your one black Hookup Wire.

In this final picture, I go back an test each of my lights to ensure nothing happened to their connections. You will see the Hookup wire is much easier to put into the tester than the Magnet Wire. Only put one Red Wire into the Tester at a time. I know you may want to put all 5 Red wires into the Tester to see all the lights work at one time but you run the Risk of Blowing out one of your LEDs...trust me, I learned the hard way on that one. AGAIN, The Tester is only designed to test ONE LED at a time.

The next step will be to install the Resistors onto the Power Management Board.

We are going to start with taking the Power Distribution Board out of the Package and turning it over to Side B. This is where we will install the resistors.

In the picture below, I have circled the area where the Resistors will be installed. Since we have 5 Lights I'm installing, I will install 5 resistors.

The first step is to apply some Low Temp Solder using our Low Temp Soldering Iron to each pad where the resistors will be mounted.

Now we are going to take one of the resistors out of the bag and install into onto the two pads we just applied Solder. There is no top or bottom or front or back on these resistors. I typically install the resistors with the number facing up so I can see what type of resistor I installed. 1001 = 1K resistor. If I was using a 3K resistor for my HO Builds, it would read 3001.

Now take your Low Temp Soldering Iron and touch each of the pads where we are going to install the resistor to heat up the Solder. Then immediately with a pair of tweezers, pick up the resister and set it on the Solder Pads. You then want to go back with the Low Temp Soldering Iron and touch the Solder again around both sides of the Resistor until its in place. I wish I could give you better instructions for this step but its going to be trail and error on your behalf to get the resistor installed correctly. You also may need to go back with a little more Low Temp Solder and apply it to both sides of the resistor. Dont worry if it looks messy...no one is going to see this Power Board.

Once you believe the resistor is installed correctly like shown in the previous picture, its now time to test the Resistor. Take your Meter and put it on the setting all the way to the right. I'm sure there is a technical term for that position but I dont know what it is called. Then taking the two end leads of the meter, place one tip on the solder joint at the bottom of the resistor and place the other tip on the Pad located just above the resistor. See the picture below for an example of the locations. It doesnt matter which tip is Red and which is Black. When looking at your meter, we are looking for it to read somewhere around 1.00 since we installed a 1K resistor. Usually when I install them, they will read .998 or .996...somewhere around 1.00. If I was installing a 3K resistor, the meter would probably read 2.99 or 2.98.

This concludes the instructions of how to install a resistor. Since I have 5 lights, I'm going to install the 5 resistors as shown in the picture below.

Next up is how to install the hookup wire to the Power Distribution Board...

Ok, to install the 5 Red Hookup Wires, they are going to be attached to the Power Distribution Board to the Solder Pads that are directly to the Right of the 5 Resistors I just installed. To each of those 5 locations, lets prepare that area by applying solder to each of those pads with the Low Temp Soldering Iron and the Low Temp Solder. The picture below shows you what that should look like when youre done.

Before we install the 5 Red Hookup Wires, let's prepare the area where we will connect the 1 Black Hookup Wire (known as the ground) to the Power Distribution Board. Flip over the Board to Side A.

When you look at the 2 connection points on the end of the Power Distribution Board, you will see a "+ " and "-". We are looking for the solid connection line that runs off of the "-". Our Black Hookup Wire (aka the Ground Wire) can been installed anywhere along this connection line. Pick a spot and apply some Low Temp Solder as seen below.

Lets now flip the Board back over to side B and start installing our 5 Red Hookup Wires. Take your Low Temp Soldering Iron and heat up one of the 5 pads that we prepared with solder. Then immediately take any one of the 5 Red Hookup Wires and hold it onto that Solder Pad with a pair of tweezers. While holding that wire in place, retouch that solder pad with the Low Temp Soldering Iron for a few seconds and remove the Soldering Iron. After a few seconds that Solder will harden and create a strong solder joint that will connect that Red Hookup Wire to your Distribution Board. If you dont feel like you have a strong enough connection, feel free to add more Solder to the Solder Pad. See the picture below for an example for the end result.

Now that I've done one, I'm going to go through and hook up the 4 remaining Red Hookup Wires following the same process.

At this point, feel free to bend those Red Hookup Wires as needed. The Solder Connections should keep the wires in place. If you happen to break a Red Connection Wire off, no big deal. Strip the end of the wire using the Wire Stripping tool I showed earlier and reconnect the end to the Solder Pad. We now need to install the 1 Black Hookup Wire. Turn the Power Distribution Board over to Side A and find that place on the "-" Solid Connection line where we applied solder earlier. Take your Low Temp Soldering Iron, reheat the solder, immediate place the Black Hookup Wire on that spot and reapply the Low Temp Soldering Iron for a few seconds. At this point all 5 Red Hookup Wires and the 1 Black Hookup Wire should be connected to your Power Distribution Board.

Next up, and the last step, is to hookup the 12V Power Supply to the Power Distribution Board.

When you take the Power Supply out of the Package, one of the 2 wires should have a white sticker on it denoting which is the positive wire and which is the negative wire. Mine did not have that sticker otherwise I would have shown you, hence I am going to have to guess. Find a set of terminal holes denoted with "+" and "-" at the end of the Power Distribution Board. It makes no difference which end you use. If you know which wire coming off your Power Supply is a "+", then feed it thru the terminal marked "+" with the unmarked wire being fed thru the "-" Terminal.

Make sure you bend the wires into a hook formation to ensure they dont slip out of the terminals as shown below.

Now the moment of truth...plug in the Power Supply to any power outlet and your LEDs should all light up. In my case, I guessed wrong on which one was the positive wire coming off my Power Supply so nothing happened. Therefore, I unplugged the Power Supply and flipped the Wires going into the "+" and "-" Terminals. I then rebent the wires and again plugged in the power supply. This time it worked. Once you can verify that you wired your Power Supply correctly to the Power Distribution Board, unplug it from the outlet and apply a little Low Temp Solder with your Low Temp Soldering Iron to those 2 connections. See Below for example.

Trouble Shooting. If one of your hookup wires comes undone or "breaks off" from the Power Distribution Board, no big deal. Just reconnect them as I described above. Do note that any time you are working on your Power Distribution Board that you first unplug it.

One other tip when applying solder, you are going to find that many times smoke will come off your soldering iron and will blow up into your face. You do NOT want to breathe in those fumes. One thing I do when applying Solder is I continually blow on the area I'm Soldering - until I'm done Soldering - to ensure I dont breathe in that smoke.

Below is a picture of the lights working.

Thanks for following along. Feel free to shoot me a message if you have questions or need help trouble shooting your project.

Alan

Well worth the effort the lighting is just the right amount it shows off all of the details,

Good Job

Carl

Bill

If I could share one tip, here's something that Dustin (Coors2U) told me about. You can buy pre-wired LED's on eBay. For me, soldering the magnet wire to the LED's is one of the worst parts of the process. I don't want to steer business away from Bill S, however neither supplier offers a pre-wired option.

The downside is that these LED's come from China or Hong Kong and take a while to arrive in the states--2-3 weeks is the norm. But, shipping is free.

Here's the same LED's that Allen uses in this tutorial: 20 of them pre-wired for $15:

http://www.ebay.com/itm/T3020WM-20pcs-Pre-soldered-micro-litz-wired-leads-Warm-White-SMD-Led-3020-NEW-/262500083759?hash=item3d1e39682f:g:DAUAAOSwGvhT340R

evemodel_es is the eBay seller I've purchased from and had no trouble.

Again…I buy ALL of my other lighting supplies from Microlumina. But to spare me the hassle of the most difficult step in the process, I took a chance on these.

The ones in pic 2, are quite a bit thinner--magnet wire thickness or thereabouts. The LED's are quite a bit smaller too (less than a millimeter). Not a great picture, but here's a bundle of 20:

And here's a bundle of 20 with the thicker wire:

If you go this route, it's worth noting that You really have to keep track of the wires since there's no red and green. They're both copper color or that silver color. A colored sharpie will do the trick.

Bill

The smaller LEDs are C0603WM. The auction lists them as 20pcs Pre-soldered micro 0.1mm Copper Wired WARM WHITE SMD. Here's the direct link:

http://www.ebay.com/itm/C0603WM-20pcs-Pre-soldered-micro-0-1mm-Copper-Wired-WARM-WHITE-SMD-Led-0603-NEW-/221513993078?hash=item3393434b76:g:R3oAAOSwxCxT3z0x

Mine came with a resistor soldered to the end of one wire. Not sure why since that's not how it was described in the auction. With the resistor on there, it'll never make it through the goose neck tubing that Alan talked about. If you follow his directions above (concerning current limiters or using the distribution board) the resistor isn't necessary.

For the project I'm currently working on, I plan on snipping off that resistor, fishing the wires through the tubing and wiring it per his instructions.

To that end...I did a little more research. I have .025 stainless tubing to be used as the conduit for the goose neck. In HO, that would equal a piece of conduit about 2" (1 1/8" in O scale). It's a tad big for HO, but acceptable in the overall scheme. The next size smaller (.018) scales out better in HO but is a real challenge to fish the LED wires through. They'll fit...however you'll find yourself wasting a lot of time and using swear words with every other breath!

Here are some pictures. The figure is HO. The larger tubing is the one that's wired (the unwired tubing is pictured for size reference. Tough to see a difference) The red wire is a strand of magnet wire--darn near the same size as the pre-wired LED:

Let there be light!

Here's a red LED (C0603R):

This one is warm white (C0603WM):

And finally, the LED with the thicker wire--also warm white. (T0402WM):

These are the only three sizes/colors that I bought. Search eBay for those model numbers. The tubing is from Bill Sartore at Microlumina. Part numbers:

.018" N2018-4

.025" N2025-4

Bill

You appear to have electricuted your LP.

Can you show the method you use to hookup your Leds? What I mean by that is do you use a power distribution board like I do where I run all the LEDs thru resistors? Also, what type of power supply do you use? As I showed it, I use a 12v plug in power supply which requires that you plug it into a wall socket. I know Kenny used some type of contraption when he lit up his Loco Shops diorama that allowed him to power his LEDs using a battery. Kenny, if you happen to read this post, maybe you can explain what you used....

Thanks!

Alan

For the Twin Mills, I used current limiters along with the LED's powered by a 9v battery.

The lighting diagram looks like this:

Alan

Bill - no worries on getting pre-wired LEDs. I even show pictures of them in my clinic; mainly to compare wire size and orientation on the LED. Nice to see my old diagram!

Yes brownbr - wiring LEDs can be a pain but it is second nature to me now and the job can be rather relaxing while listening to some music. It's not for everyone though.

Since I'm a distributor for Ngineering products I can discount and save anyone some bucks. I'm switching to a different E-Store so that managing and updating the Microlumina site will be easier for me and the wife. So keep checking Microlumina.com in the days ahead for a big change with more products listed. I don't always keep a lot of the Ngineering LEDs in stock because they're a little pricey. But if someone really needs them (they're incandescent colored LEDs are unique) feel free to drop me a line and I'll getcha some. I had about $700 (my cost) worth of Ngineering LEDs go missing at a local train show and I never really built that inventory back up. Oh well...

Bill S. (Microlumina)