Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- 992 All Categories

- 3 Picture Posting and Resizing

- 60 New Member Introductions

- 118 Off-Topic Forum

- 2 Photography

- 2 Resources

- 18 New Product Information

- 170 The SierraWest Forum

- 12 Brett's Blog

- 120 General News & Ramblings

- 3 Re-Release Information

- 6 Q & A about SierraWest

- 9 What Would You Like to See?

- 409 Builds

- 146 HO Scale Builds

- 184 O Scale Builds

- 58 Finished SW Build Pics

- 15 Miscellaneous Builds

- 194 Techniques

- 19 Working with Wood

- 23 Painting Castings

- 4 Masonry

- 23 Scenery

- 37 Tools and Supplies

- 22 Layout Planning & Building

- 40 Miscellaneous

- 20 Prototype Information

- 19 Reference and Research

How do you light your Diorama?

All,

I have been working on my wood cutters shack and have been looking through how others are doing their lighting. Personally, i followed Alan's tutorial below for the most part. however, i chose to use smaller LED's. But, all of the other products and processes are the same. Alan's tutorial did not show the implementation from a mechanics perspective as to how he connected everything on his diorama from the bottom.

So, i thought this would be an opportunity for us to share how we are going about doing it from the ground up as it were. i would be interested to see how others are taking care of wire management on the bottom of their diorama. i'm just kind of winging it based off of what i think others likely have done.

http://www.craftsmankituniversity.com/vanforum/index.php?p=/discussion/778/lighting-clinic/p1

Below is how i'm approaching my wood cutters shack wiring. This will be pretty simple with a total of 6 LED's. 5 will be constant on LED's and one will be on a fireplace simulator.

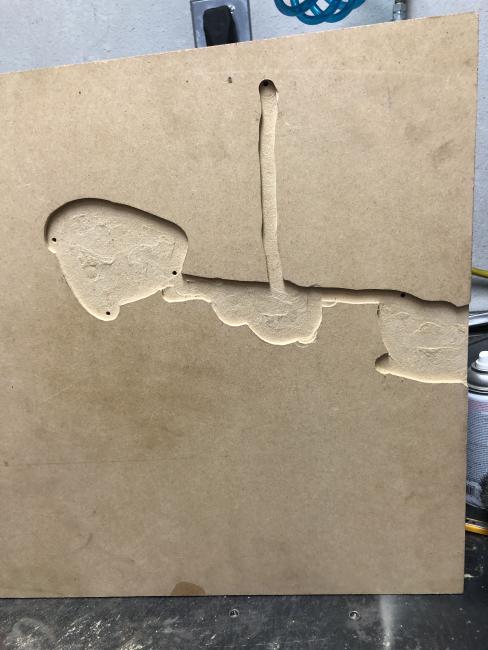

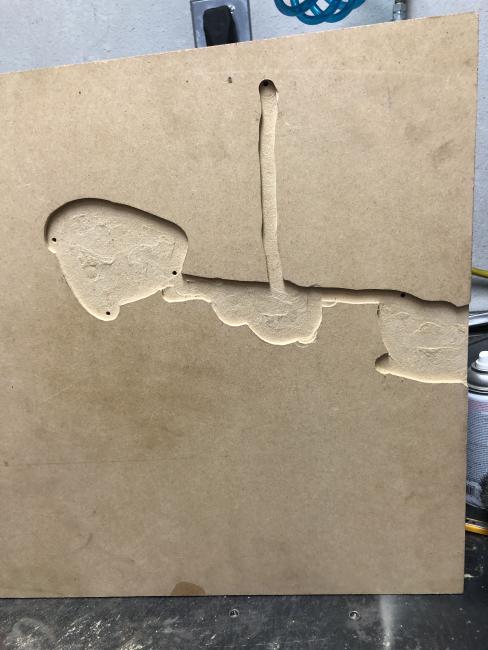

For each of the LED's i gave my self 12-15" or so of a lead wire. I wanted more than i would need to make wiring the circuit up on the bottom as easy as possible. Then, i dry set my structures and used a pair of tweezers to start the hole in the foam. Next i used a drill to finish the hole. After i had my holes drilled i used a finish router to connect all of the holes in the mdf. This way the wires will be recessed as the diorama sits on a table or whatever. This will also allow for recessed switches as well. When i started to fish my leads through the base i found that using some wire helped tremendously, it gave me something to fish the lead through with while but adding some weight to the lead as i was gluing the structure down. This help pull the wired down as i moved stuff, the magnetic wire has nearly no weight.

Here are some photos that i took over the last two days.

I have been working on my wood cutters shack and have been looking through how others are doing their lighting. Personally, i followed Alan's tutorial below for the most part. however, i chose to use smaller LED's. But, all of the other products and processes are the same. Alan's tutorial did not show the implementation from a mechanics perspective as to how he connected everything on his diorama from the bottom.

So, i thought this would be an opportunity for us to share how we are going about doing it from the ground up as it were. i would be interested to see how others are taking care of wire management on the bottom of their diorama. i'm just kind of winging it based off of what i think others likely have done.

http://www.craftsmankituniversity.com/vanforum/index.php?p=/discussion/778/lighting-clinic/p1

Below is how i'm approaching my wood cutters shack wiring. This will be pretty simple with a total of 6 LED's. 5 will be constant on LED's and one will be on a fireplace simulator.

For each of the LED's i gave my self 12-15" or so of a lead wire. I wanted more than i would need to make wiring the circuit up on the bottom as easy as possible. Then, i dry set my structures and used a pair of tweezers to start the hole in the foam. Next i used a drill to finish the hole. After i had my holes drilled i used a finish router to connect all of the holes in the mdf. This way the wires will be recessed as the diorama sits on a table or whatever. This will also allow for recessed switches as well. When i started to fish my leads through the base i found that using some wire helped tremendously, it gave me something to fish the lead through with while but adding some weight to the lead as i was gluing the structure down. This help pull the wired down as i moved stuff, the magnetic wire has nearly no weight.

Here are some photos that i took over the last two days.

Comments

I tend to run all wires to one location then run them down through the base as a bundle. I'll make a hole and use a straw as a liner.

One tip I found when using magnet wire is to tie a knot at the end of each pair of wires. This way I don't get confused on which 2 wires go together.

As for underneath the dio, mine are usually a mess. I'll cut the wires to length leaving a few inches to work with (tie another knot). I usually make a cutout for the board and batteries and screw and/or epoxy into place. I use painter tape to secure the wires. Found this much easier to remove should I need to re-do a solder point.

I was trying to think of a way that would be the least painful to do this..

Next is to cut stand off's. i ordered some Delrin that i'll machine on the lathe then drill and tap for the power distribution board.

I hope this helps someone else in the future.

i added the plug as well, i didn't want the diorama hard wired to the power supply. I thought about adding a switch. But, plugging or unplugging the diorama isn't a big deal.