Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- 954 All Categories

- 3 Picture Posting and Resizing

- 60 New Member Introductions

- 100 Off-Topic Forum

- 2 Photography

- 2 Resources

- 18 New Product Information

- 164 The SierraWest Forum

- 11 Brett's Blog

- 120 General News & Ramblings

- 3 Re-Release Information

- 1 Q & A about SierraWest

- 9 What Would You Like to See?

- 405 Builds

- 145 HO Scale Builds

- 185 O Scale Builds

- 58 Finished SW Build Pics

- 11 Miscellaneous Builds

- 185 Techniques

- 19 Working with Wood

- 23 Painting Castings

- 4 Masonry

- 16 Scenery

- 37 Tools and Supplies

- 22 Layout Planning & Building

- 38 Miscellaneous

- 19 Prototype Information

- 18 Reference and Research

SWSM CHB New Detail Castings

I purchased some of the latest O-Scale CHB castings from Brett. I had my order in hand in three days so I started to experiment with blackening the details. I thought I would share the results of my experiment and solicit any suggestions or comments. Remember these are not painted yet, just blackened. But the results are interesting and may have possible uses within our modeling repertoire.

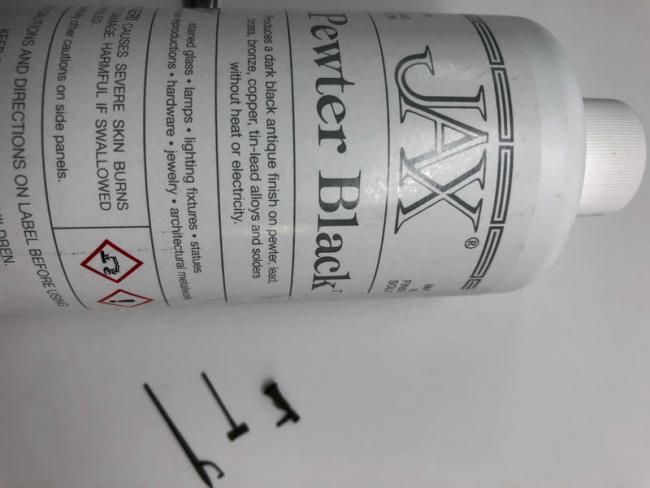

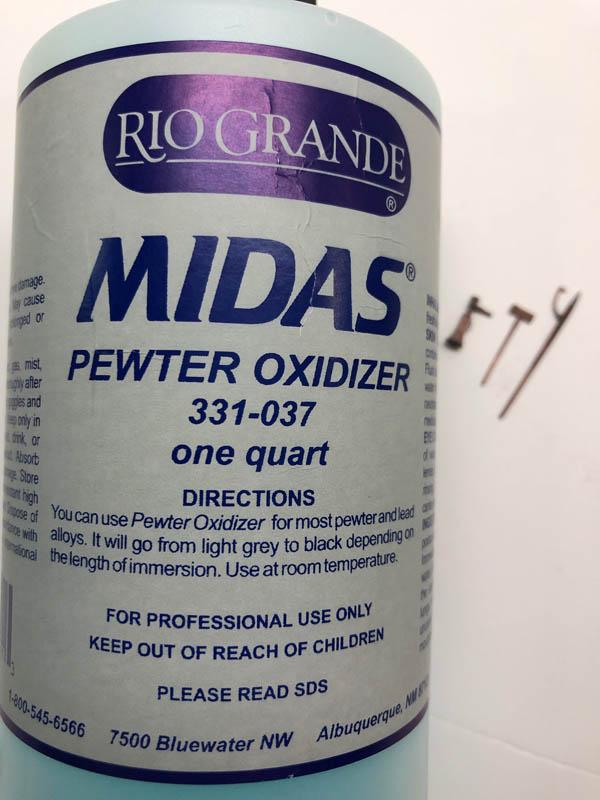

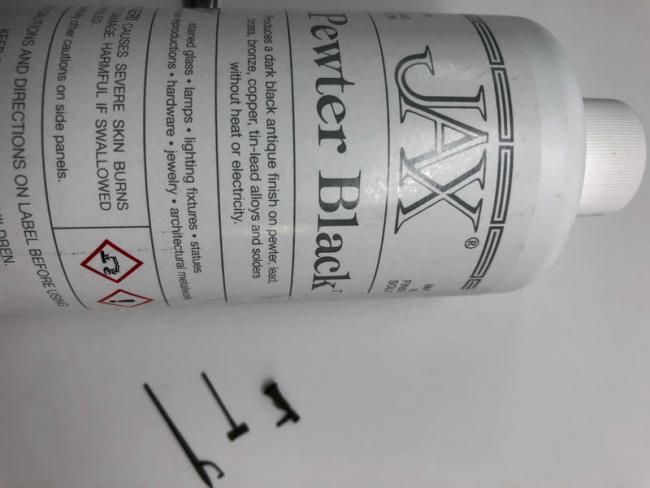

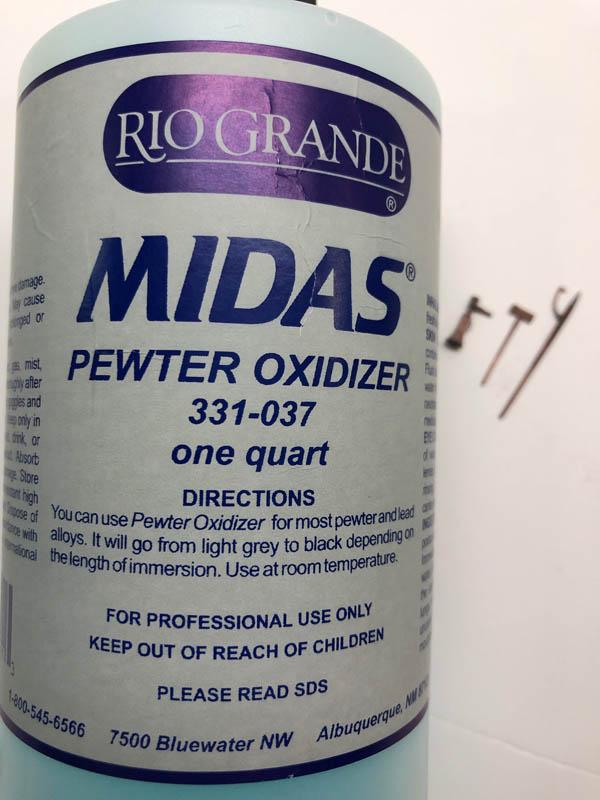

I have on hand some Jax Pewter Black as well as some RioGrande Midas Pewter Oxidizer. I have tried both of these products in the past with very different results to the pewter castings I was using. I thought that for this posting I would show the results of three experiments and post the results.

Process:

Step one for all the parts was to wash them with 99% isopropyl alcohol to prepare them for blackening/oxidizing

Step two for all the details was to carefully, watchfully dip them in the blackening agents described below to make certain

they didn't overcook.

Results: (L to R) Posted Below

#1: SWSM/CHB Original castings (Screw Jack, Axe, Peavy)

#2: SWSM/CHB Pewter castings dipped in Jax

#3: SWSM/CHB Pewter castings dipped in Midas Pewter Oxidizer

#4: SWSM/CHB Pewter castings dipped in Jax, allowed to dry overnight, then dipped in Midas Oxidizer.

Later, Dave S. Tucson, AZ

I have on hand some Jax Pewter Black as well as some RioGrande Midas Pewter Oxidizer. I have tried both of these products in the past with very different results to the pewter castings I was using. I thought that for this posting I would show the results of three experiments and post the results.

Process:

Step one for all the parts was to wash them with 99% isopropyl alcohol to prepare them for blackening/oxidizing

Step two for all the details was to carefully, watchfully dip them in the blackening agents described below to make certain

they didn't overcook.

Results: (L to R) Posted Below

#1: SWSM/CHB Original castings (Screw Jack, Axe, Peavy)

#2: SWSM/CHB Pewter castings dipped in Jax

#3: SWSM/CHB Pewter castings dipped in Midas Pewter Oxidizer

#4: SWSM/CHB Pewter castings dipped in Jax, allowed to dry overnight, then dipped in Midas Oxidizer.

Later, Dave S. Tucson, AZ

Comments

Were you going to buff them with a Dremel tool?

Always great to hear from you.

I don't plan on using a Dremel tool to buff the castings as they are very delicate. I am afraid it would tear them apart. Perhaps it was you and maybe someone else on the SWSM Forum that warned against using a Dremel tool to buff out the castings.

I may either use 0000 steel wool or the Dremel buffing pad and buff by hand. Hoping to save some of the oxidation or blackening in the minute pits on the tool faces. I already tried buffing an axe blade face with my fingers and I could see some very small darkened pits in the face after buffing. Thought it looked realistic but from about 6 inches away no one would probably notice.

Thanks, Later, Dave

Use a Dremel buffing wheel in your hand to polish the castings. Use the steel wool lightly to put an edge on the axe. I think you'll like that.

Thanks for the feedback.

Yes, the Midas Pewter Oxidizer does give an interesting finish. I am also building a 1934 Ford Berkshire Valley pewter pick-up truck model and used the Midas for that undercoat. I think the larger truck pieces better illustrate what a unique finish you can get straight out of the dipping process.

Later, Dave S Tucson, AZ

I have not had any problem using the Dremel tool with a buffing wheel on the metal castings.

Thanks for that feed back. You are doing it on HO scale detail pieces and I am doing it for O-Scale detail pieces. Hmm! Guess I'll need to do a trial piece with a very light touch and a good grip so it doesn't go flying across the room.

Later, Dave S Tucson, AZ

Nice article. Your pictures and comparisons are very informative, and a great addition to this topic. Thanks

Bill

Thanks for the feed-back. A while back I saw an advertisement for the RioGrande Midas Pewter Oxidizer solution and thought I'd investigate. Interesting thing was it didn't require any special shipping. I am up to buffing the castings as suggested (thanks for that tip Brett) and even to somewhat apprehensively using my Dremel with a polishing wheel (thanks for the encouragement Steve) to get a unique finish. Not sure it will show in the photos I will try to post soon, but there are subtle color variations and even a few minute (while realistically scaled) pits in the axe blade.

Steve,

Thanks for the encouragement to try/use my Dremel after all to polish the axe head. I did use it and while it was a bit of trial and error (a few axe handle bends to straighten out) I like the ultimate results. Not sure anyone other than myself will get close enough to see the results, but I know they are there and ultimately that is what counts.

Later, Dave S. Tucson, AZ

I learned that I had to really be aware that the Dremel Tool head is rotating clockwise when you face the front of the tool and thus counterclockwise when the tool is pointed away from the operator. While buffing one face/side of the axe head that was away from me worked alright I had to reverse the direction of the axe head 180 degrees to buff the opposite face/ side to keep from lifting the axe head and bending the axe handle.

I have always felt that even the slowest speed of my Dremel is to fast for most modeling operations. I think I will check into a rheostat switch to slow down the speed as well to make buffing a bit easier.

Thanks, Dave S. Tucson, AZ

Just a thought. .........Carl............